Robotics automation for business efficiency: key insights

Robotics automation enhances business efficiency by increasing productivity, reducing errors, and allowing for safer, more precise operations across various industries.

Robotics automation for business efficiency is becoming a game-changer for companies looking to optimize their operations. Have you ever wondered how your competitors are achieving remarkable productivity? Let’s dive into the transformative power of robotics automation.

Understanding robotics automation

Understanding robotics automation is essential for businesses seeking to enhance efficiency and productivity. This technology involves the use of robotic systems to automate complex processes, which can significantly reduce human intervention and errors.

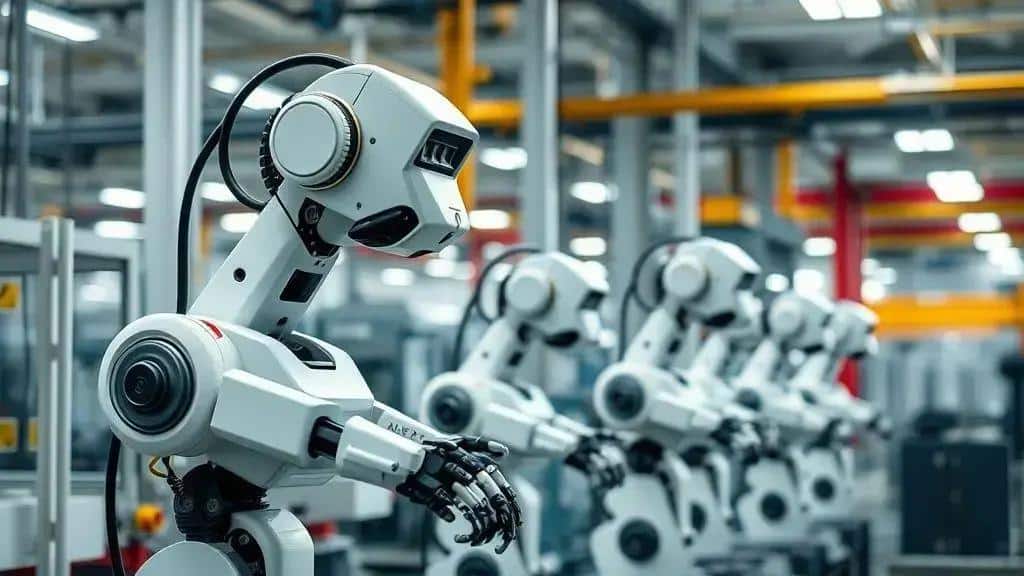

When we think about robotics automation, it’s important to recognize its various applications across different industries. In manufacturing, for instance, robots can perform tasks such as assembling products, welding, and painting with great precision. They can work tirelessly and can often complete jobs faster than a human worker.

Key Features of Robotics Automation

Robotics automation offers several key features that can revolutionize business operations:

- Increased Productivity: Robots can operate 24/7, leading to higher output levels.

- Consistency and Quality: Robotics ensures that tasks are completed with a uniform quality, thereby reducing defects.

- Cost Savings: Over time, automation can lead to significant labor and operational cost reductions.

Moreover, the implementation of robotics automation can lead to improved safety in the workplace. Robots can handle dangerous tasks that would put human workers at risk, reducing the likelihood of workplace injuries.

As technology advances, we are witnessing the integration of artificial intelligence and machine learning with robotics. This combination allows for smarter systems that can adapt to changing conditions and improve their performance over time.

Real-World Examples

Various companies have successfully adopted robotics automation. For instance, automotive manufacturers use robotic arms to assemble vehicles with speed and precision. In logistics, companies utilize automated guided vehicles (AGVs) to transport goods efficiently.

In summary, understanding robotics automation can greatly benefit businesses looking to innovate and remain competitive. By leveraging robotic technologies, companies can achieve operational excellence and enhance their overall productivity.

Benefits of robotics in business

The benefits of robotics in business are numerous and impactful. Companies across various sectors are increasingly adopting robotics to streamline operations and enhance efficiency. By incorporating robots, businesses can achieve significant improvements in productivity and cost savings.

One major advantage of using robotics is the ability to enhance output. Robots can perform repetitive tasks quickly and accurately, allowing human workers to focus on more complex activities that require critical thinking. This not only accelerates production but also contributes to better resource management.

Key Advantages of Robotics

Here are some of the main benefits that robotics can provide:

- Increased Efficiency: Robots can work continuously without breaks, which maximizes productivity.

- Improved Precision: Automation reduces human errors in manufacturing processes, leading to higher quality products.

- Cost Reduction: By increasing efficiency and productivity, businesses can lower their overall operational costs.

Additionally, the integration of robotics improves workplace safety. Robots can handle dangerous tasks, which reduces the risk of injury among employees. For example, in warehouses, robots can lift heavy items, allowing workers to avoid potential strains or accidents.

As industries evolve, businesses that adopt robotics are often seen as leaders in innovation. This can enhance a company’s reputation and market position. With technology constantly advancing, the capabilities of robotics are only expected to grow, paving the way for new opportunities.

Long-Term Impact

In the long run, businesses that embrace robotics tend to navigate market challenges more effectively. They can adapt quickly to changing demands and leverage technology for competitive advantage. The benefits touch every aspect of operations, from supply chain management to customer service.

Ultimately, understanding the benefits of robotics in business can help leaders make informed decisions about technology investments that drive success and innovation.

Implementing robotics for efficiency

Implementing robotics for efficiency is a key step for businesses looking to enhance their operations. It requires planning and execution to ensure that the technology integrates seamlessly into existing workflows. By utilizing robotics, organizations can automate mundane tasks and allow employees to focus on more strategic efforts.

When considering robotics, it’s useful to evaluate several factors that contribute to successful implementation. These elements create a clear framework for integration.

Steps for Successful Implementation

Here are essential steps that businesses can follow to implement robotics effectively:

- Assess Needs: Identify areas where robotics can add value, such as production, assembly, or inventory management.

- Choose the Right Technology: Select robotic systems that align with your specific requirements and business goals.

- Training and Support: Provide training for staff to adapt to new technology, ensuring a smoother transition.

Following these steps can make the path to robotics implementation more manageable. It is also crucial to evaluate the impact on team dynamics and to maintain open communication throughout the process.

Additionally, successful implementation may involve testing the robotics in phases. Starting with a pilot program allows businesses to monitor performance and make adjustments before a full rollout. This method reduces risks and helps in determining the most effective use of robotics.

Continuous Improvement

After integrating robotics for efficiency, businesses should focus on continuous improvement. Regular reviews and updates can optimize the robotic systems, ensuring they meet evolving business needs. Feedback from employees can also offer insights into enhancing automation efforts.

Overall, implementing robotics for efficiency is not just a technological change; it’s about transforming how a business operates. This transformation can lead to significant gains in productivity, cost savings, and operational excellence.

Future trends in robotics automation

Future trends in robotics automation are shaping the way businesses will operate in upcoming years. As technology continues to advance, businesses are eager to adopt these innovations to stay competitive. With the rise of artificial intelligence (AI) and machine learning (ML), the capabilities of robots are expanding beyond simple automation tasks.

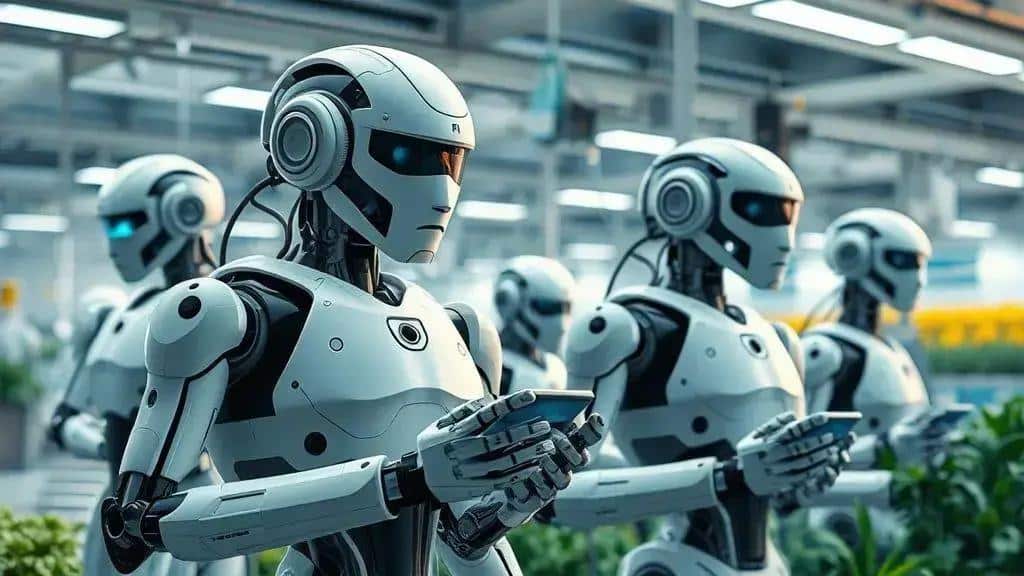

One significant trend is the increased use of collaborative robots, also known as cobots. These robots work alongside human workers and are designed to assist rather than replace them. By handling repetitive or dangerous tasks, cobots can improve safety and enhance productivity, allowing humans to focus on more strategic functions.

Key Trends to Watch

Here are some of the exciting trends to keep an eye on in the realm of robotics automation:

- AI Integration: The combination of AI with robotics will lead to smarter systems that can learn and adapt to their environment.

- Increased Customization: Businesses will demand more customizable robots that can be tailored to specific needs, enhancing operational flexibility.

- Rise of Autonomous Robots: Autonomous robotics will become more prevalent, taking on tasks in logistics, agriculture, and more without human intervention.

Another trend involves the expansion of robotics into new industries. Fields such as healthcare and agriculture are recognizing the benefits of automation. Robots can perform surgeries with precision or assist with planting and harvesting crops. These applications will likely lead to improved outcomes and increased efficiency.

Moreover, as technology becomes more affordable, small and medium-sized enterprises (SMEs) are increasingly able to adopt robotics automation. This democratization of technology opens up new opportunities for businesses of all sizes to enhance their operations.

Implications for the Workforce

The future of robotics automation also raises questions about the workforce. As robots take over routine tasks, the demand for skilled workers who can manage and maintain these systems will grow. This shift emphasizes the need for training programs to prepare the workforce for new roles in a more automated environment.

Overall, the future of robotics automation holds exciting potential for businesses looking for efficiency and innovation. By staying informed about these trends, companies can position themselves for success in a rapidly evolving landscape.

In conclusion, the future of robotics automation offers exciting possibilities for businesses. By embracing these advancements, companies can improve efficiency and productivity, ensuring they stay competitive in a fast-changing market. It is vital for organizations to keep an eye on emerging trends, such as AI integration and autonomous systems, as they can help transform operations. Additionally, investing in employee training will be essential to adapt to new technologies. Overall, robotics automation is not just about machines; it is about creating a collaborative environment that enhances the workforce and drives innovation.

FAQ – Frequently Asked Questions about Robotics Automation

How can robotics automation improve business efficiency?

Robotics automation speeds up production, reduces errors, and allows workers to focus on more strategic tasks, boosting overall efficiency.

What industries are benefiting from robotics automation?

Industries like manufacturing, healthcare, and agriculture are seeing significant advantages from robotics automation in processes like assembly, surgery, and farming.

What are collaborative robots (cobots)?

Collaborative robots, or cobots, are designed to work alongside humans, assisting them with tasks and increasing safety and productivity.

How can businesses prepare their workforce for robotics automation?

Businesses can provide training programs to help employees learn how to work with new robotic systems and adapt to changing roles as automation increases.