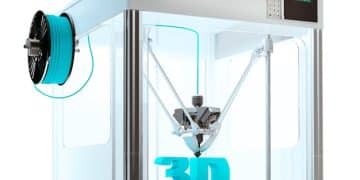

3D Printing Revolution: Transforming US Manufacturing and Healthcare

3D printing is revolutionizing manufacturing and healthcare in the US, offering customized solutions, accelerating production, and reducing costs across various applications.

3D printing: revolutionizing manufacturing and healthcare in the US, is changing how industries operate in many ways. It is offering unprecedented levels of customization, efficiency, and cost-effectiveness.

The Rise of 3D Printing in the US

3D printing, also known as additive manufacturing, has rapidly evolved from a niche technology to a mainstream solution. This rise is particularly noticeable in the US, where innovation drives adoption across entire industries.

The US has become a global hub for 3D printing technology, and several factors contribute to this growth, including a robust ecosystem of research institutions, startups, and established manufacturers.

With advancements in materials, software, and hardware, 3D printing offers capabilities previously unimaginable.

Key Drivers of Adoption

Several key factors are driving the adoption of 3D printing across various industries in the US.

- Customization: Providing solutions tailored to the user needs is invaluable.

- Efficiency: Rapid prototyping and on-demand manufacturing reduce lead times significantly.

- Cost-Effectiveness: Reducing waste and optimizing material usage can lower costs.

- Innovation: Facilitating the creation of complex geometries and novel designs is a huge advantage.

The impact of 3D printing is being felt in industries ranging from aerospace to consumer goods, creating ripple effects throughout the US economy.

Manufacturing Transformation

One of the most significant impacts of 3D printing is in the manufacturing sector. This technology is transforming traditional processes, offering a versatile and efficient alternative.

Manufacturers are leveraging 3D printing to streamline operations, reduce costs, and accelerate production cycles. The ability to quickly produce prototypes and customized parts makes 3D printing a game-changer for the industry.

Advantages in Manufacturing

3D printing offers distinct advantages in US manufacturing, contributing to increased competitiveness and innovation.

- Prototyping: Accelerating the design and testing phases with rapid prototyping capabilities.

- On-Demand Manufacturing: Producing parts only when needed, reducing inventory costs.

- Complex Geometries: Creating intricate designs that are impossible with traditional methods.

- Material Innovation: Experimenting with new materials and composite structures is an important advantage.

The role of 3D printing in manufacturing is set to expand as technology continues to advance and adoption rates increase.

Healthcare Revolution

In healthcare, 3D printing is revolutionizing patient care, offering custom solutions tailored to the unique needs of individual patients. From prosthetics to surgical planning, the technology is improving outcomes and quality of life.

Healthcare providers in the US are increasingly adopting 3D printing to create personalized medical devices, implants, and surgical guides. This improves precision and efficiency of surgical procedures, minimizing risks, and optimizing patient outcomes.

Applications in Healthcare

The applications of 3D printing in healthcare are incredibly diverse, ranging from simple tools to complex implants.

- Prosthetics: Creating personalized prosthetics that improve comfort and functionality for patients.

- Implants: Producing custom implants matched to the specific anatomy of each patient.

- Surgical Planning: Providing detailed 3D models for surgeons to practice complex procedures.

- Drug Delivery: Developing customized drug delivery systems that release medication precisely where needed.

As innovation in 3D printing continues, the potential for transforming healthcare in the US is immense.

Aerospace and Automotive Industries

Beyond healthcare and manufacturing, the aerospace and automotive industries are also benefiting significantly from 3D printing. These sectors are implementing 3D printing to create lightweight components, optimize designs, and reduce production costs.

Aerospace companies in the US leverage 3D printing to produce complex parts for aircraft and spacecraft. The ability to create lightweight, high-strength components is critical for improving fuel efficiency and performance.

Automotive manufacturers use 3D printing to prototype new designs, create customized parts, and personalize vehicles. This enhances innovation and enables faster time-to-market for new products.

Advantages in Aerospace and Automotive

3D printing provides crucial advantages in terms of design freedom, weight reduction, and rapid prototyping.

- Lightweight Components: Creating lightweight parts that improve fuel efficiency and performance.

- Design Freedom: Producing complex geometries that are impossible with traditional methods.

- Rapid Prototyping: Accelerating the design and testing phases for new products.

- Customization: Providing solutions tailored to specific needs and applications.

The adoption of 3D printing is expected to rise in these industries, driving innovation and enhancing competitiveness.

Challenges and Future Trends

Despite its numerous benefits, 3D printing faces several challenges, including material limitations and scalability issues. Addressing these challenges is crucial for further expansion and integration of the technology.

Research and development efforts are focused on creating new materials with enhanced properties and improving printing speeds to facilitate mass production. Overcoming these barriers will be critical for realizing the full potential of 3D printing.

Future Trends in 3D Printing

Several trends are likely to shape the future of 3D printing in the US including advances in metal 3D printing.

- Materials Innovation: Developing new materials with enhanced strength, durability, and functionality.

- Printing Speed: Improving printing speeds to enable mass production and reduce lead times.

- Software Integration: Integrating 3D printing software with CAD/CAM systems for seamless workflow.

- Sustainability: Promoting sustainable practices in 3D printing, such as material recycling and waste reduction.

The future of 3D printing is promising, with opportunities to transform various industries and improve the lives of people across the US.

Economic and Societal Impact

The rise of 3D printing has significant economic and societal implications for the US, including job creation, economic growth, and improved access to healthcare. As the technology becomes more accessible and affordable, its impact is expected to become even more profound.

The growth of 3D printing has created new jobs in manufacturing, engineering, and design. This expansion contributes to economic growth. Simultaneously, it also improves access to customized medical solutions & products.

Positive Impacts of 3D Printing

3D printing brings several beneficial impacts to the society.

- Job Creation: Creating new opportunities in additive manufacturing and related fields.

- Economic Growth: Driving innovation and competitiveness in US industries.

- Healthcare Access: Improving access to personalized medical devices and treatments.

- Sustainability: Promoting sustainable manufacturing practices and reducing waste.

The economic and societal impacts of 3D printing are poised to shape the future of the US.

| Key Point | Brief Description |

|---|---|

| 🚀 Manufacturing Revolution | Transforms prototyping, on-demand production, and complex designs. |

| 🏥 Healthcare Advancements | Enables custom prosthetics, implants, and surgical planning models. |

| 🚗 Aerospace & Automotive | Creates lightweight components, optimizes designs, and reduce costs. |

| 💡 Economic Impact | Drives job creation, economic growth, and improves healthcare access. |

FAQ

▼

3D printing, also known as additive manufacturing, is a process of building three-dimensional objects from a digital design. It involves layering materials, such as plastic, metal, or composite, to create the final product.

▼

In healthcare, 3D printing is used for creating custom prosthetics, implants, surgical planning models, and drug delivery systems. These applications help improve patient outcomes and personalize treatments.

▼

3D printing offers several benefits in manufacturing, including rapid prototyping, on-demand production, reduced costs, and the ability to create complex geometries otherwise impossible with traditional manufacturing.

▼

3D printing faces challenges such as material limitations, scalability issues, and the need for improved printing speeds. Overcoming these challenges is critical for its widespread adoption.

▼

The future of 3D printing involves innovations in materials, higher printing speeds, better software integration, and greater sustainability. These advances will drive further adoption and transformation across industries.

Conclusion

In conclusion, 3D printing: revolutionizing manufacturing and healthcare in the US is a transformative technology driving significant advancements in numerous sectors. Despite existing challenges, the continuous innovation and increasing adoption promise to reshape industries, improve healthcare outcomes, and foster economic growth across the United States.