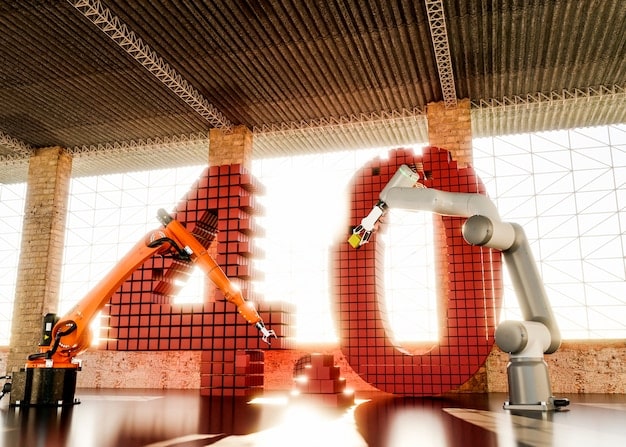

US Manufacturing Automation: Job Creation Impact by 2025

A projected 12% increase in US manufacturing automation by 2025 is expected to reshape the job market, potentially leading to both job displacement in routine tasks and the creation of new roles in areas like robotics maintenance, data analysis, and advanced manufacturing technologies.

The rise of automation in US manufacturing is no longer a futuristic concept but a rapidly unfolding reality. The projected 12% increase in US manufacturing automation by 2025 begs the question: How Will the Projected 12% Increase in US Manufacturing Automation Impact Job Creation by 2025? Let’s delve into the potential impacts, exploring both challenges and opportunities.

Understanding the Automation Trend in US Manufacturing

Automation is transforming the manufacturing landscape, driven by the need for increased efficiency, reduced costs, and improved product quality. The US manufacturing sector is at the forefront of this technological revolution.

Drivers of Automation

Several factors are fueling the automation trend in US manufacturing. Companies are seeking to optimize production processes and gain a competitive edge.

- Labor Costs: Automating tasks reduces reliance on manual labor, particularly in regions with high labor costs.

- Improved Efficiency: Automated systems operate continuously and consistently, minimizing errors and maximizing output.

- Enhanced Quality: Robots and automated machines perform tasks with greater precision, leading to higher product quality and reduced defects.

The adoption of automation technologies is not uniform across all manufacturing sectors. Industries like automotive and electronics have been quick to embrace automation due to the repetitive and high-volume nature of their production processes. However, other sectors are gradually integrating automation as the technology becomes more accessible and cost-effective.

Job Displacement: Assessing the Risks

One of the primary concerns surrounding manufacturing automation is its potential to displace workers in routine and repetitive tasks. The economic and social ramifications of job losses need careful consideration.

Impact on Specific Roles

Certain job roles are more susceptible to automation than others. These roles typically involve tasks that are easily programmable and require minimal human judgment.

- Assembly Line Workers: Robots excel at assembling components on a production line, replacing the need for human workers in these tasks.

- Machine Operators: Automated machines can perform many of the tasks previously done by human operators, such as loading materials and monitoring performance.

- Quality Control Inspectors: Computer vision systems and sensors can detect defects with greater accuracy, reducing the need for human inspectors.

While the potential for job displacement is a valid concern, it’s important to recognize that automation doesn’t necessarily equate to mass unemployment. Instead, it often leads to a shift in the types of jobs available and the skills required.

The Rise of New Job Roles: Automation’s Silver Lining

While automation may displace workers in some areas, it also creates new job opportunities in fields related to design, implementation, maintenance, and support of automated systems. These new roles require a higher level of technical expertise.

Roles in Robotics and Automation

The increasing adoption of robots and automated systems is driving demand for workers with specialized skills in robotics and automation.

- Robotics Technicians: These professionals install, maintain, and repair robots, ensuring their smooth operation.

- Automation Engineers: Automation engineers design and implement automated systems, optimizing processes and integrating robots into the production line.

- Data Analysts: With the vast amounts of data generated by automated systems, data analysts are needed to interpret the information and identify areas for improvement.

The emergence of these new job roles necessitates a focus on retraining and upskilling the existing workforce. Workers who are displaced by automation can acquire new skills that enable them to transition to these higher-paying and more rewarding jobs.

Retraining and Upskilling Initiatives: Preparing the Workforce

To mitigate the negative impacts of job displacement and prepare workers for the changing demands of the manufacturing sector, effective retraining and upskilling programs are essential.

Government and Industry Partnerships

Governments and industry leaders must collaborate to develop and implement comprehensive retraining initiatives. These programs should focus on providing workers with the skills they need to succeed in the automated workplace.

- Community Colleges: Community colleges can play a vital role in offering courses and certifications in robotics, automation, and data analytics.

- Apprenticeships: Apprenticeship programs provide hands-on training and mentorship, allowing workers to learn new skills while earning a paycheck.

- Online Learning Platforms: Online platforms offer flexible and accessible learning opportunities, enabling workers to acquire new skills at their own pace.

The success of retraining initiatives depends on their ability to adapt to the evolving needs of the manufacturing sector. Programs must be continuously updated to reflect the latest technological advancements and ensure that workers are equipped with the most relevant skills.

The Economic Impact: Productivity Gains and Growth

The increased automation in US manufacturing has the potential to drive significant economic growth through improved productivity, reduced costs, and enhanced competitiveness.

Increased Efficiency and Output

Automated systems can operate continuously and consistently, leading to increased efficiency and higher output. This allows manufacturers to produce more goods with fewer resources, boosting profitability and competitiveness.

Automation can also enable manufacturers to customize products and respond quickly to changing market demands. This flexibility is particularly important in today’s fast-paced and dynamic business environment.

Addressing the Challenges: Ensuring a Smooth Transition

While automation offers numerous benefits, it also presents challenges that must be addressed to ensure a smooth transition and mitigate potential negative impacts on workers and communities.

Investing in Education and Training

Investing in education and training programs is crucial to equip workers with the skills they need to thrive in the automated workplace. This includes providing access to affordable and high-quality education and training opportunities.

Furthermore, it’s important to foster a culture of lifelong learning, encouraging workers to continuously update their skills and adapt to new technologies.

| Key Aspect | Brief Description |

|---|---|

| 🤖 Automation Growth | Projected 12% increase in US manufacturing by 2025. |

| 💼 Job Displacement | Risk in routine tasks; requires retraining efforts. |

| 🛠️ New Job Roles | Demand for robotics technicians and automation engineers. |

| 📈 Economic Impact | Potential for productivity gains and economic growth. |

Frequently Asked Questions

▼

The main force is the need for enhanced efficiency, lower costs, and improved product quality to stay competitive in the global market.

▼

Roles involving repetitive tasks like assembly line work and machine operation are highly susceptible to being automated.

▼

New jobs include robotics technicians, automation engineers, and data analysts, requiring technical skills to manage automated systems.

▼

Workers can take advantage of retraining and upskilling programs focused on robotics, automation, and data analysis to adapt to new roles.

▼

Automation can lead to productivity gains, reduced costs, and enhanced competitiveness, driving economic growth for manufacturing companies.

Conclusion

The projected increase in US manufacturing automation presents both challenges and opportunities. While job displacement is a concern, the rise of new job roles and the potential for economic growth offer a path forward. By investing in education, training, and support for workers, the US can harness the benefits of automation while mitigating its negative impacts.