The Future of Robotics in US Manufacturing: Automation and Efficiency in the US

The future of robotics in US manufacturing is characterized by increasing automation and efficiency, driven by technological advancements and the need for enhanced productivity and competitiveness.

The integration of the future of robotics in US manufacturing: automation and efficiency is rapidly transforming industries across the nation, promising increased productivity, reduced costs, and enhanced competitiveness. As technology advances, understanding the implications and opportunities becomes crucial for businesses looking to thrive in the modern landscape.

The Rise of Robotics in US Manufacturing

Robotics has emerged as a pivotal force in US manufacturing, reshaping traditional processes and driving unprecedented levels of efficiency. This transformation is fueled by advancements in artificial intelligence, machine learning, and sensor technology, making robots more adaptable, intelligent, and capable of performing complex tasks.

Historical Context of Robotics in Manufacturing

The introduction of robots in manufacturing dates back to the mid-20th century, primarily for simple, repetitive tasks. Over the decades, the capabilities of robots have expanded significantly, allowing them to handle more intricate operations and collaborate with human workers.

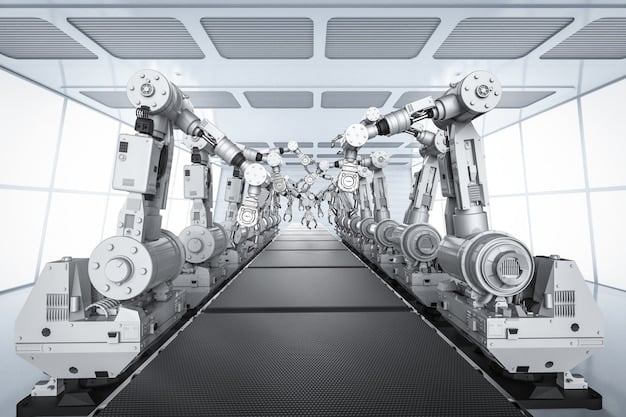

Current Applications of Robotics

Today, robots are employed across various manufacturing sectors, including automotive, aerospace, electronics, and pharmaceuticals. They perform tasks such as welding, painting, assembly, and material handling with greater precision and speed than ever before.

Robots are increasingly integrated into manufacturing processes due to their ability to enhance production speed and reduce error rates. Here are some benefits that companies are leveraging to improve operation and production.

- Increased Productivity: Robots can operate 24/7 without breaks, leading to higher output and faster turnaround times.

- Improved Quality: Robots ensure consistent and precise execution, reducing defects and improving product quality.

- Enhanced Safety: Robots can handle dangerous or hazardous tasks, minimizing risks to human workers.

- Reduced Costs: While the initial investment can be significant, robots lower labor costs and reduce waste in the long run.

In summary, the rise of robotics in US manufacturing represents a significant shift towards greater automation and efficiency. Companies that embrace these technologies stand to gain a competitive edge in the global market.

Key Drivers of Automation in Manufacturing

Several factors are driving the increasing adoption of automation in US manufacturing. These drivers include the need to enhance productivity, reduce costs, improve product quality, and address labor shortages. Automation technologies like robotics, AI, and IoT are central to achieving these goals.

Demand for Increased Productivity

Manufacturers are constantly seeking ways to increase production output while maintaining or reducing costs. Automation provides a means to achieve higher levels of productivity by enabling machines to work faster and more consistently than humans.

Need for Cost Reduction

High labor costs, rising material prices, and fierce competition are pressuring manufacturers to find cost-effective solutions. Automation helps reduce labor expenses, minimize waste, and optimize resource utilization.

Focus on Enhanced Product Quality

Consumers demand high-quality products with minimal defects. Automation ensures consistency and precision in manufacturing processes, leading to improved product quality and customer satisfaction.

The following are a couple of industries that have been early adopters of automation. Their business functions are improved with the help of robotics.

- Automotive Industry: Automated assembly lines, robotic welding, and painting processes are used to produce vehicles efficiently and consistently.

- Electronics Manufacturing: Robots handle delicate components, perform precision assembly, and ensure high-quality standards in electronics production.

- Food and Beverage: Automated packaging, sorting, and processing systems enhance hygiene and efficiency in food and beverage production.

In conclusion, the demand for increased productivity, cost reduction, and enhanced product quality are the primary drivers of automation in US manufacturing. By leveraging advanced technologies, manufacturers can achieve these objectives and stay competitive.

Impact of Robotics on Workforce and Jobs

The integration of robotics in US manufacturing is sparking significant debates about its impact on the workforce and job market. While automation brings numerous benefits, concerns about job displacement and the need for workforce retraining are prominent.

Job Displacement Concerns

One of the main concerns is that robots will replace human workers, leading to job losses in manufacturing. Tasks that are repetitive, dangerous, or physically demanding are most susceptible to automation.

Creation of New Job Roles

Despite job displacement concerns, the robotics revolution also creates new job opportunities. These roles include robot programmers, technicians, maintenance personnel, and data analysts who are needed to design, operate, and maintain robotic systems.

The Skills Gap and Retraining Initiatives

The changing nature of manufacturing jobs necessitates workforce retraining and upskilling programs. Initiatives that focus on STEM (science, technology, engineering, and mathematics) education can prepare workers for the jobs of the future.

Here are types of job title that will increase in demand as more companies look to add automation.

- Robot Technicians: Professionals who install, maintain, and repair robotic systems.

- Data Analysts: Experts who analyze data generated by robots to optimize manufacturing processes.

- AI Specialists: Professionals who develop and implement AI algorithms to enhance robot intelligence and capabilities.

In essence, the impact of robotics on the workforce is multifaceted. While some jobs may be displaced, the creation of new, higher-skilled roles and the need for workforce retraining offer pathways to a more adaptable and resilient manufacturing sector.

Technological Advancements in Robotics

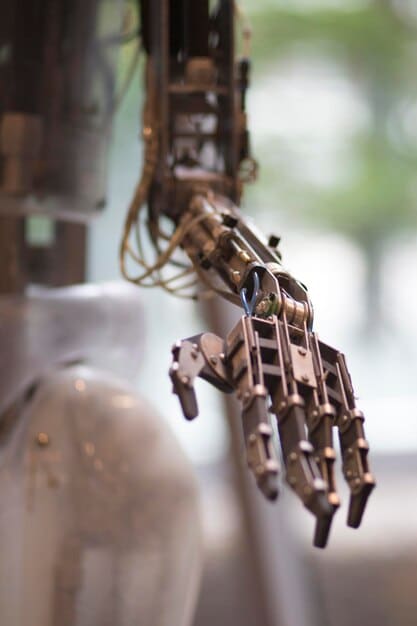

The future of robotics in US manufacturing is being shaped by rapid technological advancements that are enhancing the capabilities, adaptability, and intelligence of robots. These innovations include AI-powered robots, collaborative robots (cobots), and advanced sensor technologies.

AI-Powered Robots

Artificial intelligence is transforming robots from simple machines into intelligent systems capable of learning, problem-solving, and decision-making. AI-powered robots can analyze data, optimize performance, and adapt to changing conditions in real-time.

Collaborative Robots (Cobots)

Cobots are designed to work alongside human workers in shared workspaces. They are equipped with sensors and safety features that allow them to operate safely around people, performing tasks that require collaboration and flexibility.

Advances in Sensor Technologies

Advanced sensor technologies, such as vision systems, force sensors, and proximity sensors, enable robots to perceive their environment with greater accuracy. These sensors allow robots to perform complex tasks, such as object recognition, manipulation, and quality control.

The list below includes some innovations in automation robotics.

- Machine Learning: Robots can learn from data and experience, improving their performance over time.

- Computer Vision: Robots can see and interpret images, enabling them to perform tasks that require visual perception.

- Natural Language Processing: Robots can understand and respond to human language, facilitating communication and collaboration.

In summary, technological advancements in AI, cobots, and sensor technologies are driving the evolution of robotics in US manufacturing. These innovations are leading to more efficient, flexible, and intelligent manufacturing processes.

Challenges and Opportunities in Robotics Adoption

While the adoption of robotics in US manufacturing offers numerous benefits, it also presents several challenges and opportunities for manufacturers. Overcoming these challenges and capitalizing on the opportunities is crucial for successful integration of robotics technologies.

High Initial Investment Costs

The initial investment required to purchase and implement robotic systems can be significant. Small and medium-sized enterprises (SMEs) may find it difficult to afford the upfront costs, hindering their ability to adopt automation technologies.

Integration Complexities

Integrating robots into existing manufacturing processes can be complex and time-consuming. It requires careful planning, system design, and coordination between different departments to ensure seamless integration.

Cybersecurity Risks

As robots become more connected and integrated into manufacturing networks, they become vulnerable to cybersecurity threats. Manufacturers must implement robust security measures to protect their robotic systems from cyberattacks and data breaches.

This is a list of solutions that manufacturers can use to overcome obstacles related to integration.

- Government Incentives: Tax credits, grants, and subsidies can help manufacturers offset the initial costs of robotics adoption.

- Robotics-as-a-Service (RaaS): RaaS models allow manufacturers to lease robots instead of purchasing them outright, reducing upfront investment costs.

- Training Programs: Investing in training programs can equip workers with the skills needed to operate and maintain robotic systems.

In conclusion, while the adoption of robotics presents challenges such as high initial investment costs and integration complexities, these can be addressed through strategic planning, government incentives, and workforce development initiatives. Capitalizing on these opportunities will enable manufacturers to fully leverage the benefits of robotics.

Future Trends in Robotics and Manufacturing

The future of robotics in US manufacturing is set to witness further advancements and transformations, driven by emerging technologies and evolving industry needs. These trends include the increasing use of digital twins, the integration of 5G technology, and the rise of sustainable manufacturing practices.

Digital Twins

Digital twins are virtual replicas of physical assets, processes, or systems. They allow manufacturers to simulate and optimize manufacturing operations, predict equipment failures, and improve product designs.

5G Technology

The deployment of 5G technology will enable faster and more reliable communication between robots, machines, and control systems. This will lead to enhanced real-time monitoring, control, and optimization of manufacturing processes.

Sustainable Manufacturing

As environmental concerns grow, manufacturers are increasingly adopting sustainable practices to reduce waste, conserve energy, and minimize their carbon footprint. Robots can play a key role in enabling sustainable manufacturing by optimizing resource utilization and reducing energy consumption.

The following includes a list of ideas to consider when taking sustainability into account.

- Additive Manufacturing (3D Printing): Reduces material waste and enables the production of customized products.

- Energy-Efficient Robots: Incorporating energy-efficient components and control algorithms can reduce energy consumption.

- Recycling and Reuse: Robots can be used to sort and process recyclable materials, promoting the circular economy.

In summary, the future of robotics in US manufacturing will be shaped by trends such as digital twins, 5G technology, and sustainable manufacturing practices. By embracing these trends, manufacturers can achieve new levels of efficiency, innovation, and sustainability.

| Key Point | Brief Description |

|---|---|

| 🚀 Increased Productivity | Robots operate 24/7, boosting output and reducing turnaround times. |

| 🛡️ Enhanced Safety | Robots handle dangerous tasks, minimizing risks to human workers. |

| 🤖 AI-Powered Robots | AI enables robots to learn, problem-solve, and adapt in real-time. |

| 🌱 Sustainable Manufacturing | Robots optimize resource utilization and reduce energy consumption. |

Frequently Asked Questions

▼

Robotics enhances efficiency by automating repetitive tasks, reducing error rates, and operating continuously without breaks, leading to higher production output and faster turnaround times.

▼

Cobots, or collaborative robots, offer the advantage of working safely alongside human workers in shared workspaces, performing tasks that require collaboration and flexibility.

▼

Digital twins provide virtual replicas of physical assets, allowing manufacturers to simulate and optimize operations, predict equipment failures, and improve product designs.

▼

5G technology enables faster and more reliable communication between robots, machines, and control systems, leading to enhanced real-time monitoring and optimization of manufacturing processes.

▼

Robots contribute to sustainability by optimizing resource utilization, reducing waste, conserving energy, and facilitating the recycling and reuse of materials in manufacturing processes.

Conclusion

In conclusion, the future of robotics in US manufacturing holds immense potential for driving automation and efficiency. By embracing technological advancements, addressing challenges strategically, and fostering workforce development, manufacturers can unlock new levels of productivity, innovation, and sustainability.