3D Printing Revolution: Transforming US Manufacturing and Healthcare

The 3D printing revolution is transforming manufacturing and healthcare in the US by enabling rapid prototyping, customized medical solutions, and efficient production processes.

The 3D printing revolution: transforming manufacturing and healthcare in the US is no longer a futuristic fantasy but a tangible reality reshaping industries and improving lives. From creating intricate medical implants to streamlining production processes, additive manufacturing is making its mark. What potential does it truly hold?

Understanding the 3D Printing Revolution in the US

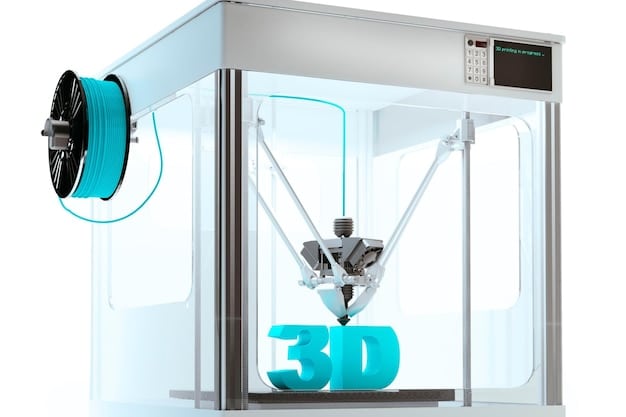

3D printing, also known as additive manufacturing, is revolutionizing various sectors across the United States. By building objects layer by layer, it offers unparalleled design freedom and customization. This transformative technology is impacting manufacturing and healthcare in profound ways.

The Basics of 3D Printing

3D printing works by creating three-dimensional objects from a digital design. Unlike traditional subtractive manufacturing, where material is removed, 3D printing adds material layer by layer, allowing for complex geometries and intricate designs.

Different 3D Printing Technologies

Various 3D printing technologies exist, each with its own strengths and applications. These include Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Direct Metal Laser Sintering (DMLS). Each method utilizes different materials and processes to achieve the desired outcome.

- Fused Deposition Modeling (FDM): Uses thermoplastic filaments to build parts.

- Stereolithography (SLA): Employs UV lasers to cure liquid resin layer by layer.

- Selective Laser Sintering (SLS): Uses lasers to sinter powdered materials into solid structures.

- Direct Metal Laser Sintering (DMLS): A metal 3D printing process used to make parts for aerospace, automotive, and medical devices.

In summary, 3D printing technology is more than just an innovative trend; it is a cornerstone of modern manufacturing and healthcare advancements in the US.

Transforming the US Manufacturing Landscape

The integration of 3D printing into the US manufacturing sector is causing significant changes. It enables companies to produce goods more efficiently, reduce waste, and create highly customized products. This revolution is boosting innovation and competitiveness.

Rapid Prototyping

One of the most significant benefits of 3D printing is its ability to facilitate rapid prototyping. Manufacturers can quickly create and test designs, accelerating the product development cycle and reducing time to market.

Customization and Mass Personalization

3D printing allows for mass personalization, enabling manufacturers to create products tailored to individual customer needs. This capability opens new markets and enhances customer satisfaction by offering products that are precisely suited to their requirements.

- Aerospace Industry: Producing lightweight components and customized parts for aircraft.

- Automotive Industry: Creating prototypes and tooling, as well as custom car parts.

- Consumer Goods: Manufacturing personalized products like eyewear and footwear.

Ultimately, the transformation of the US manufacturing landscape through 3D printing represents a shift towards more agile, responsive, and innovative production methods.

Revolutionizing Healthcare in the US

The healthcare sector in the US is undergoing a massive transformation, thanks to 3D printing. From personalized implants to surgical planning tools, this technology is enhancing patient care and improving medical outcomes. Its precision and customization capabilities are invaluable.

Personalized Implants and Prosthetics

3D printing is enabling the creation of personalized implants and prosthetics that perfectly match a patient’s anatomy. This results in better fit, improved functionality, and enhanced comfort, leading to higher patient satisfaction.

Surgical Planning and Education

3D-printed anatomical models are used for surgical planning, allowing surgeons to visualize complex cases and practice procedures before the actual surgery. These models also serve as valuable educational tools for medical students and residents.

- Dental Implants: Creating custom dental implants that offer a precise and comfortable fit.

- Orthopedic Implants: Manufacturing personalized joint replacements and bone grafts.

- Surgical Guides: Producing guides that enhance the accuracy of surgical procedures.

In conclusion, the healthcare revolution spurred by 3D printing is paving the way for more personalized, precise, and effective medical treatments in the United States.

Materials and Innovation in 3D Printing

Advancements in materials science are driving innovation in 3D printing, leading to the development of new materials with enhanced properties. This expansion is enabling a wider range of applications and improving the quality of 3D-printed products.

New Polymers and Composites

The development of new polymers and composites with improved strength, durability, and flexibility is expanding the possibilities of 3D printing. These materials are being used in various applications, from aerospace components to consumer goods.

Metal Alloys and Ceramics

Innovations in metal alloys and ceramics are enabling the production of high-performance parts with excellent mechanical properties. These materials are essential for applications in aerospace, automotive, and medical industries.

- Titanium Alloys: Used in aerospace and medical implants for their high strength and biocompatibility.

- Carbon Fiber Composites: Employed in automotive and sports equipment for their lightweight and high strength.

- Advanced Ceramics: Utilized in high-temperature applications and medical devices for their durability and inertness.

Overall, materials innovation is a crucial factor in the ongoing advancement of 3D printing, unlocking new possibilities and enhancing the performance of 3D-printed products.

Challenges and Opportunities in the 3D Printing Industry

While 3D printing offers significant advantages, it is not without its challenges. Addressing these challenges and seizing emerging opportunities is crucial for the continued growth and success of the 3D printing industry in the US. Overcoming these hurdles is essential for widespread adoption.

Scalability and Cost

One of the main challenges is scaling up production to meet increasing demand while keeping costs competitive. Improving the speed and efficiency of 3D printing processes is essential for making it a viable option for mass production.

Material Limitations

Expanding the range of materials that can be used in 3D printing is another key challenge. Developing new materials with enhanced properties and reducing material costs are vital for broadening the applications of 3D printing.

- Investment in R&D: Focusing on research and development to overcome material limitations and improve printing processes.

- Collaboration: Fostering collaboration between industry, academia, and government to drive innovation and address challenges.

- Standards and Regulations: Establishing clear standards and regulations to ensure the quality and safety of 3D-printed products.

In summary, addressing the challenges and seizing the opportunities in the 3D printing industry requires a concerted effort to innovate, collaborate, and establish clear standards, paving the way for continued growth and success in the US.

The Future of 3D Printing in the US

The future of 3D printing in the US looks promising, with ongoing advancements and increasing adoption across various industries. As technology continues to evolve, 3D printing is poised to play an even greater role in shaping the future of manufacturing and healthcare.

AI and Automation

The integration of artificial intelligence (AI) and automation is expected to further enhance the capabilities of 3D printing, enabling more efficient and precise production processes. AI can optimize designs, predict material behavior, and automate printing tasks.

Sustainable Manufacturing

3D printing offers opportunities for more sustainable manufacturing practices by reducing waste, minimizing material usage, and enabling localized production. This can contribute to a more environmentally friendly and resource-efficient economy.

- On-Demand Manufacturing: Producing goods only when needed, reducing waste and inventory costs.

- Localized Production: Manufacturing products closer to the point of consumption, reducing transportation costs and emissions.

- Recycled Materials: Using recycled materials in 3D printing, promoting a circular economy.

In conclusion, the future of 3D printing in the US is bright, with ongoing advancements and increasing adoption promising to transform manufacturing and healthcare, driving innovation, and fostering sustainability.

| Key Point | Brief Description |

|---|---|

| 🚀 Rapid Prototyping | Speeds up development by quickly creating and testing designs. |

| 🩻 Personalized Implants | Creates implants and prosthetics that perfectly match patient anatomy. |

| 🔩 Material Innovation | New materials with better properties for wider applications. |

| 🤖 AI Integration | AI optimizes designs and automates printing for efficiency. |

FAQ Section

▼

3D printing, or additive manufacturing, builds objects layer by layer from a digital design. It uses materials like plastics, metals, or ceramics to create three-dimensional objects.

▼

3D printing enables rapid prototyping, mass personalization, and on-demand manufacturing, allowing companies to produce goods more efficiently and customize products for individual needs.

▼

In healthcare, 3D printing is used for personalized implants, surgical planning, and creating anatomical models, enhancing patient care and improving medical outcomes.

▼

Challenges include scalability, high costs, and material limitations. Addressing these requires investment in R&D, collaboration, and the establishment of clear standards and regulations.

▼

The future involves AI integration, sustainable manufacturing practices, and wider adoption across industries, promising increased efficiency, innovation, and environmental benefits.

Conclusion

In summary, the 3D printing revolution: transforming manufacturing and healthcare in the US is significantly impacting various sectors. By understanding its basics, embracing its innovations, and addressing its challenges, the US can continue to lead in this transformative technology, enhancing its manufacturing capabilities and healthcare outcomes.